Refrigerants used in heat pumps are potent greenhouse gases. This post collects data points on the prevalence of heat pump refrigerant leaks, the significance of leaks, and the regulatory and industry response.

The prevalence of leaks has to be considered unknown, but 100% refrigerant loss over a pump’s lifetime is a conservative guess as to the average, triangulating among the various observations below. My own belief is that average lifetime refrigerant loss rates are higher than 100% considering the following realities:

- Even a significant leak will not lead to complete failure of performance. It may result in cooler supply air from a heat pump operated for heating, but still warm enough to keep a customer from detecting a problem. I am unaware of any long term follow-up studies of heat pumps installed.

- HVAC installers and repair people are the only people positioned to report accurately on the prevalence of detected leaks. Generally, they have a disincentive to report leaks as they may be fairly or unfairly attributed to errors in workmanship. The pitiful response rate in the UK log book study below testifies to installer reticence.

- There is high risk of sloppy disposal at the time of decommissioning, especially in a demolition context.

- My two own heat pumps have each lost over 100% of their charge through repeated leaks within the first 18 months of operation. I hear too many reports of similar experiences — including reports of installers (unlike my own) who do not do the time-consuming work of sleuthing the leaks, who instead just refill the system repeatedly.

- My recent informal survey of 229 homeowners with heat pumps showed that 7% of those with one or fewer heating seasons of use had experienced leaks.

The California Public Utilities Commission assumes life cycle losses at over 150% of refrigerant charge with roughly half of the loss occurring through power disposal at end of life. See this Refrigerant Avoided Cost Calculator

Prevalence of refrigerant leaks

Leaks are intrinsically difficult to quantify. They happen unpredictably and they are not events that all installers are eager to document (see the low response rate in the UK consulting firm study below). The sources listed below make a range of estimates. Taken together they suggest average annual leakage rates of 3-5%, which over a 17 year life translates into 50 to 85% leakage. Additional leakage can occur in installation, servicing, and especially in decommissioning. State planning documents do not attempt to estimate leakage, but acknowledge the risk.

- “There are aspects of future F-gas emissions that are not known well-enough to represent them in this model. One example is the rate of F-gas leakage from heat pumps deployed at large scales. These are relatively new technologies in the Massachusetts marketplace, and as they become more standard, it remains to be seen if best practices are adopted for service and end-of-life management.” Massachusetts 2050 Decarbonization Roadmap Study, Non-energy Sector Technical Report.

- “Many contractors said bad installations by ‘other contractors’ hurt the heat pump market; they noted it was not uncommon to find refrigerant leaks on ductless heat pumps.” Report to Mass Save on Multifamily Heat Pump Barriers Study, March 2022.

- An IPCC group estimated leakage rates for split air conditioners (similar to heat pumps but running at lower power) at on the order of 4-5% of nominal charge per year, as compared to 2-2.5% per year for window units.

- A UK consulting firm estimated based on log books that leakage rates were on the order of 3.5% annually for domestic heat pumps, mostly due to larger leaks (median 42% of refrigerant) in about 10% of the installations. A related finding is that pump efficiency declines when leaks have reduced pressure of the refrigerant. Only 6 of 82 organizations contacted participated in the log review, so the sample may understate leakage (“Although such organisations had been assured that data would remain confidential, it seems that many perceived that there still remained a risk of adverse impacts. . ..” [page 34]) . This study was completed in 2014 and made a positive estimate of net benefits despite the leaks.

- Another source attributes an estimate of annual leaks of 6.0% for heat pumps to the UK environmental regulator.

- This refrigerant-industry-sponsored site posits a 4% annual leak rate with 15% additional at end of life.

- This CARB guide posits an annual 10% leak rate with an additional 56% loss at end of life. This seems to be a high-side assumption rather than an empirical finding. See Table 2 in the document and references at the end.

- EPA says that typical annual operational leak rate is 1-4% for small split A/C units (exclusive of additional refrigerant leaks that can occur during equipment installation, maintenance, servicing, and disposal). EPA, 2021 from UN Ozone Secretariat (2015). This translates into operational losses of 17 to 68% on an 17 year life from operations alone. Split A/C units typically run at lower power than heat pumps.

- This site offers a discussion of refrigerant market trends which is somewhat dated in light of pending EPA rule-making discussed below.

- Paper on heat pump net emissions benefit estimates 112.5% refrigerant leakage over life time. Makes estimate of savings using high renewables scenarios.

- This site makes the argument that we should use a shorter (20-year) time frame for evaluating warming impact of GHGs like refrigerants which do eventually break down in the atmosphere. In that perspective, the global warming potential of R410A, the most common refrigerant today is 4400x worse than CO2. (From the more commonly used 100-year perspective R410A is 2088x worse than CO2.)

- Heat pumps operate at higher power and over a wider range of conditions than split air conditioners and may experience higher rates of material degradation.

- While leaks are commonly detected and reported, leaks normally go undetected until performance is substantially degraded and in partial heat pump conversions, a consumer might not immediately notice performance degradation.

- One constituent reported routine re-charging of refrigerant for his family’s heat pump, so lifetime operational-only leakage of well over 100% is possible.

- A discussion of prevention of heat pump leaks, mostly focused on joint fitting techniques, recognizes the problem.

- A recent Mass Save study found leakage in 6% of sites during an approximately 1 year period. The study noted that some leaks may have been undetected.

Significance of leaks

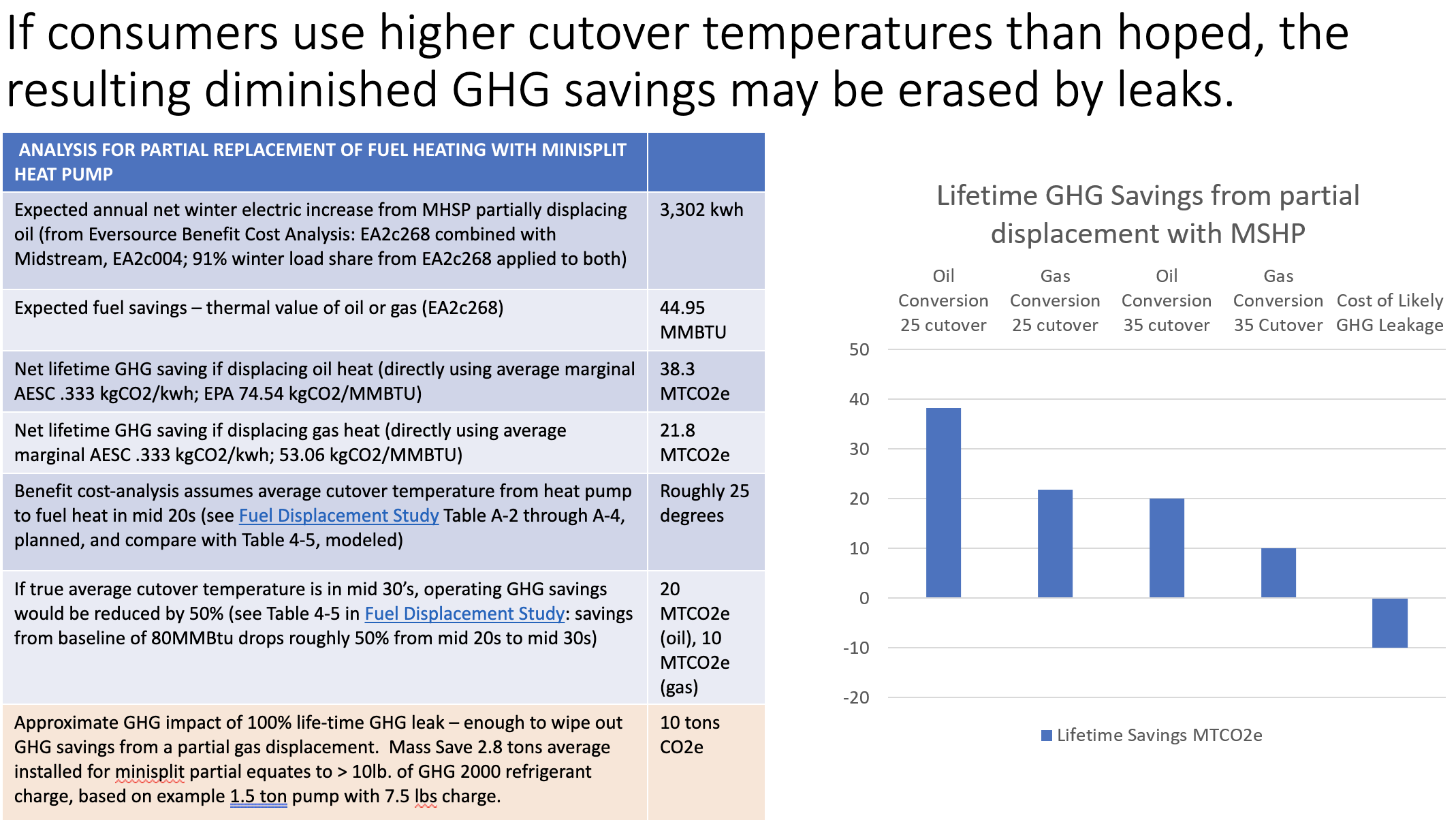

For efficient and heavily-used heat pumps, a lifetime refrigerant leakage of even 100% will easily be justified by much greater GHG savings from the operation of the heat pumps. However, a significant leak can overwhelm the savings in installations where a fossil fuel heating system is retained and the heat pump is only light used and therefore does not generate GHG savings.

Regulatory efforts to reduce F-Gases and Industry Response

- The U.S. has ratified the Kigali Amendment to the Montreal Protocol. The Montreal protocol banned ozone depleting refrigerants. The Kigali amendment banned many of the successor generation of refrigerants, hydrofluorocarbons, which although not ozone depleting, have severe global warming impact.

- Congress passed the American Innovation and Manufacturing Act directing EPA to set up a regulatory framework to phase down HFC’s

- “phase down production and consumption of HFCs to 15% of their baseline levels in a stepwise manner by 2036 through an allowance allocation and trading program”

- “maximizing reclamation and minimizing releases from equipment”

- “facilitating the transition to next-generation technologies through sector-based restrictions.”

- In December 2022, EPA proposed a rule limiting GWP to 700 in heat pump refrigerants, effective January 1, 2025 for import/manufacture and January 1, 2026 for sale. The most common current refrigerant, R-410A has a GWP of 2088.

- The Massachusetts Department of Environment Protection does regulate F-Gases, but not in heat pumps.

- Note that refrigerants are not interchangeable in heat pumps, so that consumers cannot change refrigerants without changing heat pumps – this may generate a market for secondary heat pump installations.

- Conversations with heat pump industry representatives suggest that the heat pumps developed with likely replacement refrigerants (mostly R-32) will allow heat pumps to be 10 to 15% more efficient. They are used in many other markets world-wide, but in the safety-vigilant U.S. market, the pumps will need to have better leak protections because the refrigerants will be mildly flammable. This review of the history of refrigerants and the prospects for refrigerant evolution highlights the tradeoffs between flammability, toxicity, heat pump efficiency, global warming potential, and ozone depletion potential.

- See this post for more discussion of the regulatory response.

Prevalence of refrigerant leaks: Another source corroborating your leak-rate estimates is: Table 1; Troch, Sarah, et. al.; Harmonization of Life Cycle Climate Performance (LCCP) Methodology; Purdue University; 16th International Refrigeration and Air Conditioning Conference; July 11 – 14, 2016. Troch estimates a 4% average annual leak rate, with a 15% loss at end of life, for a residential split system. With a 15 year life, that’s about 5%/year.

Ductless multi-split systems, especially those with branch boxes, probably pose the biggest concerns given the large number of field joints involved.

Consider that the timeframe for introduction of heat pumps having new refrigerants could be longer than expected, especially when deploying flammable or moderately flammable refrigerants in a litigious society. The potential for delays is significant.

Significance of Leaks: You overstate the environmental impacts of refrigerant leakage from heat pumps:

? Your unstated assumption is that the alternative to a heat pump results in no refrigerant leakage. That may be close to correct for those who would alternatively use factory-packaged window air conditioners. Window air conditioners, however, cannot begin to compete with heat pumps in terms of efficiency, comfort, noise, convenience, and aesthetics. In most cases, the alternative is a split-system air conditioner (either existing or new) that is just as prone to refrigerant leakage as a heat pump. If a homeowner’s current A/C system fails, they will either replace it with another split-system A/C system, or a heat pump. With many R-22 A/C systems reaching the end of their useful life, this is a common scenario. Therefore, the net impact of refrigerant leakage associated with installing heat pumps is probably near zero.

? Use of marginal vs. average emissions factors for electricity: If we are to achieve the goals put forth in the MA Clean Energy and Climate Plan for 2025 and 2030, in 2030, something like 20% of our total electricity consumption will be for residential heat pumps and (to a lesser extent) EV’s. [EV’s: 900,000 EV’s; 4 miles/kWh; 11,353 miles/vehicle/year] [Heat Pumps: 1 million homes; 2.7 heating seasonal efficiency; 96.6 MMBtu/year heating load (for 2,000 sq. ft. home)] [MA electricity sales: 50.8 TWh in 2021]. This is not a “marginal” change in electricity consumption. Marginal emissions factors are based on the emissions of the Locational Marginal Unit (LMU), which, in turn, is defined as “the last unit dispatched to balance the system.” [2021 ISO New England Electric Generator Air Emissions Report, Section 2.1, Paragraph 3] These LMUs are not representative of the generation mix that will be serving large numbers of heat pumps and EV’s. Average emissions factors projected over the next ~15 years would be more appropriate for estimating the carbon impacts of heat pumps. Our entire electrification strategy is based on the premise that we can supply much of our electricity from non-emitting sources. Let’s make sure we do that.

? You select heat-pump examples that may not be representative of typical installations and may underestimate the heating loads served by heat pumps. This impact will be even more pronounced as we improve home weatherization, heat-pump installation practices, and homeowner education. You show hybrid heating systems having switchover (“cutover”) temperatures of 25F to 35F. This results in 30% to 50% of the heating load being served by fossil fuels. You base these switchover temperatures on assumptions (the same assumptions used in the Fuel Displacement Study you cite)—these are not hard field data. The Mass Save program recommends switchover temperatures of 15F or lower for propane or oil, and 30F or lower for natural gas. [User tips: Ducted heat pumps] Frankly, these recommendations are conservative. If sized correctly and preceded by appropriate home weatherization measures, heat pumps can serve up to 100% of the heating load. Further, many heat-pump installations use electric-resistance supplemental heat that can operate in tandem with the heat pump at lower outdoor temperatures, resulting in much greater displacement of fossil fuels.

? You assume that refrigerant leakage is proportional to heat-pump capacity, but provide no justification for this assumption. Capacity is a function of refrigerant flow rate, not total charge. To achieve economies of scale, manufacturers sometimes use the same heat exchangers having the same internal volumes across a range of capacities. Also, the length of line sets is generally not proportional to capacity. Further, we don’t know the impacts of system charge on refrigerant leakage. For the same leak in two systems having different charges, the lost refrigerant will depend primarily on the time period before the leak is repaired (except when the leak is so large that the full charge is lost).

Thanks for weighing in, Bob. I appreciate the dialog. A few responses.

Following up on Bob Zogg’s point about air conditioner refrigerant leaks, we should consider that an air conditioner at the end of its useful life is much more likely to develop refrigerant leaks (due to metal fatigue, corrosion and other failure mechanisms) than a newly installed heat pump. Delaying the replacement of an older air conditioner to wait for promised newer technology heat pumps will on average result in increasing the amount of refrigerant leaks.

When considering the significance of leaks, we should also consider the significance of natural gas leaks on the overall emissions comparisons of natural gas heating systems versus heat pumps.

A Harvard and Boston University study found methane leakage rates of 2.7% in the Boston area natural gas distribution network. https://www.pnas.org/doi/10.1073/pnas.1416261112

Considering the significance of natural gas leaks, using a 20 year GWP potential for methane, as you suggest for refrigerants, almost doubles the emissions impacts of using natural gas to heat our homes. CO2e emissions factor rises from 11.7 pounds per therm with zero leaks to 21.3 pounds CO2e per therm with a 2.7% leakage rate.

Taking all of these factors into account, and assuming

a 3 ton cold climate heat pump with

9 pounds of R-410A refrigerant and

a 4% annual refrigerant leakage rate

delivering 94 MMBtu of heat to an average Massachusetts home, with

ISO-NE 2021 load weighted marginal emission rate

will reduce overall emissions by 66% (or 14,721 pounds of CO2e emissions per year)

Conversely, if we wait 2 to 5 years for a heat pump with a refrigerant with GWP of 4, that heat pump will reduce emissions by 73% (or 16,282 pounds of CO2e emissions per year), or about 1,562 pounds more emissions savings.

It would take the newer heat pump 19 years to make up for the natural gas emissions during a 2 year wait for new technology heat pumps and 47 years to make up for the natural gas emissions if the newer refrigerant heat pump isn’t available for 5 years.

In relation to the question about how much fossil fuels will be displaced with heat pumps, we have good news on that front. “We can’t imagine a better demonstration of how heat pump technologies can perform than during last weekend’s weather,” a Mass Save spokesperson said.

https://www.bostonglobe.com/2023/02/08/science/heat-pumps-had-their-first-major-test-last-weekend-heres-how-it-went/

I recommend using the 100 year GWP. Longer term evaluation supports a higher carbon pricing and a greater scope of carbon reducing interventions. See this discussion. This results in lower CO2e changes associated with methane emissions.

I otherwise can’t quite follow the math here: 94 MMBTU of natural gas results in 10,941 lbs of Carbon using EPA conversion factors. Not sure how your savings numbers are coming out with larger numbers for savings. Happy to review a step by step spreadsheet.